How to Select the Right THK Linear Rail for Your Application

THK linear rails are a popular choice for linear motion applications due to their high load capacity, low friction, and smooth motion. However, selecting the right THK linear rail for your application can be challenging, as there are many factors to consider. In this article, we’ll provide some tips on how to select the right THK linear rail for your specific application.

The first factor to consider when selecting a THK linear rail is the load capacity. You should choose a linear rail that can handle the weight of your application without deflecting or deforming. To determine the load capacity of a THK linear rail, you can refer to the manufacturer’s specifications or consult with a THK representative.

The second factor to consider is the travel distance. You should choose a linear rail that is long enough to accommodate the travel distance of your application. If the linear rail is too short, it can cause instability and reduce accuracy. On the other hand, if the linear rail is too long, it can increase the overall cost of the system.

The third factor to consider is the mounting style. THK linear rails are available in various mounting styles, including flange, square, and round types. You should choose a mounting style that is compatible with your application and allows for easy installation and maintenance.

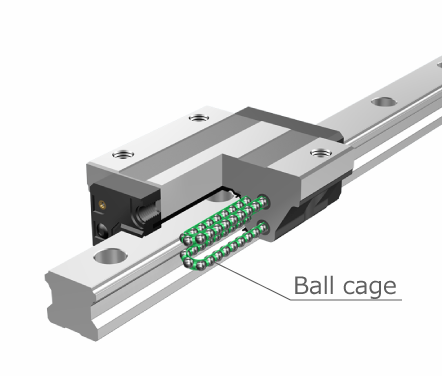

The fourth factor to consider is the type of carriage. THK linear rails come with different types of carriages, including standard, wide, and low-profile types. You should choose a carriage type that can support the load of your application and provides the necessary accuracy and stability.

The fifth factor to consider is the environment in which the linear rail will be used. If the linear rail will be used in a harsh or corrosive environment, you should choose a linear rail with a protective coating or material that can withstand the environment.

In conclusion, selecting the right TH